Scientists develop novel heat source-free thermoelectric generators from carbon nanotubes as potential power sources for wireless and wearable technology

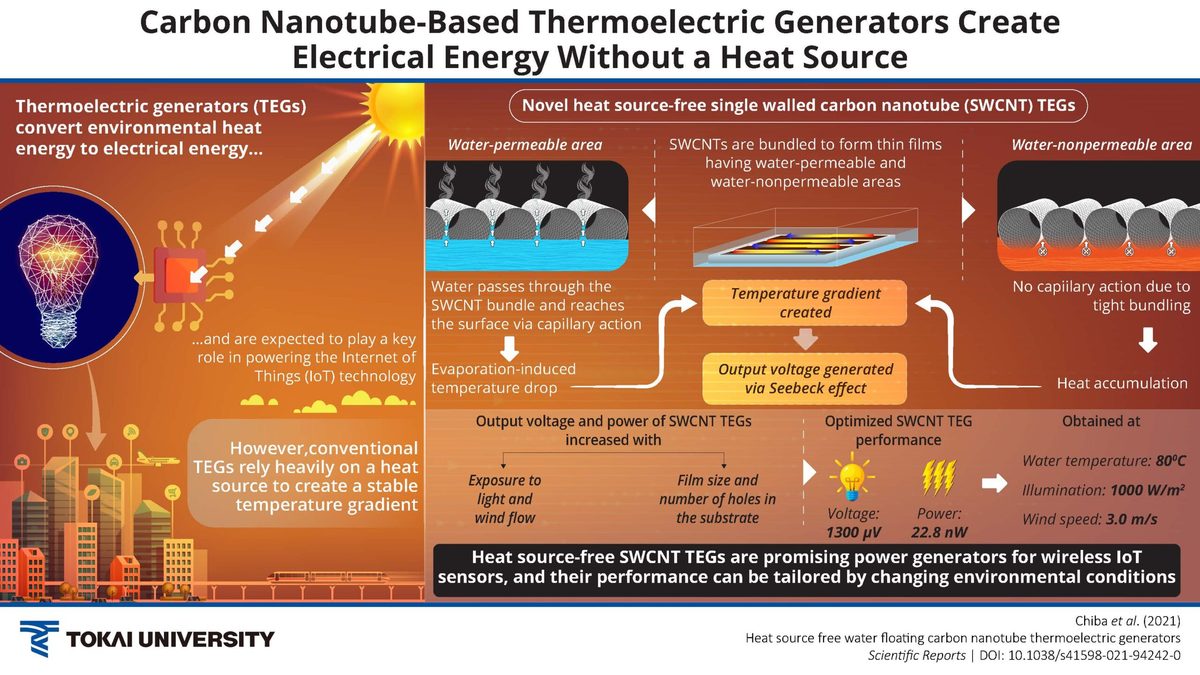

Thermoelectric generators that produce electricity from heat are limited in their applicability, owing to their heavy reliance on a heat source. To solve this issue, researchers from Tokai University, Japan, have fabricated a novel carbon nanotube-based thermoelectric generator capable of producing electricity upon contact with water, without relying on a heat source. They examine the generator’s performance and speculate that it is a promising power source for sensors widely utilized in IoT technology.

The influence of internet of things (IoT) technology has snowballed over the past few years. IoT technology can be observed in nearly every industry, ranging from automobiles and healthcare to electronics and agriculture. Most IoT systems today rely heavily on a network of sensors for their operation, which in turn work on electrical energy.

Thermoelectric generators (TEGs) – materials that produce electrical energy from heat energy – are often used as power sources for IoT sensors, owing to their lightweight and flexible properties. Most TEGs require a heat source, such as solar energy, to create a temperature difference, which in turn produces the electrical energy. However, the requirement of the constant presence of a heat source greatly restricts the applicability of TEGs in IoT systems.

Now, a research group from Tokai University, Japan, led by Dr. Masayuki Takashiri, appears to have finally solved the heat source problem for TEGs. In their study published in Scientific Reports, the team developed a TEG based on single-walled carbon nanotube (SWCNT) film that is capable of generating electrical power on contact with water. Explaining the working mechanism, Dr. Takashiri states: “There are gaps in the SWCNT structures that allow water to be sucked in due to capillary action and reach the upper surface of the film. When water evaporates from the upper surface, it results in cooling of the surface. This creates a temperature gradient in the film and electrical power is generated.”

As these SWCNT film TEGs would be used in ambient conditions, their operational stability and performance were studied under a variety of environmental conditions. The researchers reported that performance of SWCNT film TEGs improved with higher water temperature, wind speed, and illumination. The electrical voltage and power generated by the TEG was 2.5 times higher when tested with a wind speed of 3 m/s compared to that when tested without any wind. Similarly, an illumination of 1000 W/m2 resulted in a 3.7-fold increase in electrical voltage and power relative to the illumination-free measurement.

Combining all optimum conditions, i.e., high temperature (80 ᵒC), wind speed (3 m/s), and illumination (1000 W/m2), the SWCNT film TEG yielded a voltage of 1300 µV and power of 22.8 nW, which was a near 10-fold increase compared to the values observed with a water temperature of 20 ᵒC, without any wind and illumination.

The team found that the performance of SWCNT film TEGs could be optimized by controlling environmental conditions. Moreover, they also reported that reducing the size of TEG films and spacing between them results in an increase in output voltage and power. To check how the TEGs performed under actual environmental conditions, the scientists verified their operation under natural sunlight and wind and reported generation of stable output voltage in all environments during the day and night.

Surmising the relevance of these new SWCNT film TEGs, Dr. Takashiri concludes, “The areas of application of IoT sensors is going to increase. The placement of the sensors may not always allow power sources that rely on battery or heat. SWCNT film TEGs can be utilized in such scenarios. They can be used in water environments for quality monitoring sensors and also in wearable sensors that generate voltage from evaporation of sweat.”

In time, further research into the design and optimization of these novel TEGs will certainly power the creation of a safer and more convenient society.

| Authors | Tomoyuki Chiba, Yuki Amma, Masayuki Takashiri |

| Title of original paper | Heat source free water floating carbon nanotube thermoelectric generators |

| Journal | Scientific Reports |

| DOI | 10.1038/s41598-021-94242-0 |

| Affiliations | Department of Materials Science, Tokai University, Hiratsuka, Kanagawa 259‑1292, Japan |

Additional Reference information for EurekAlert

Latest Article Publication Date: 19 July 2021

Method of Research: Experimental Study

Subject of Research: Not applicable

COI Statement: The authors declare no competing interests.

Photo courtesy: Masayuki Takashiri from Tokai University

About Professor Masayuki Takashiri

Prof. Masayuki Takashiri is a Professor in the Department of Materials Science and a faculty member of the Environment and Energy Materials Lab at Tokai University, Japan. His main areas of research interest include thermoelectric materials, silicon thin-film solar cells, and thermal transport, in which he has published several studies in reputed international journals.